Thread replies: 5

Thread images: 2

Thread images: 2

Anonymous

Switching Transformers 2016-02-19 11:50:48 Post No. 948903

[Report] Image search: [Google]

Switching Transformers 2016-02-19 11:50:48 Post No. 948903

[Report] Image search: [Google]

File: transformer, maybe.jpg (51KB, 600x600px) Image search:

[Google]

51KB, 600x600px

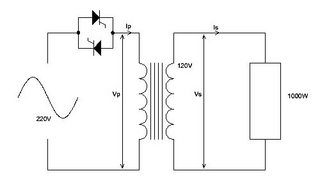

If I have a step-down transformer leading to a peltier heating element that I want to control via duty cycle, where do I put the relay?

Do I put it between the transformer and load? Does this mean that the transformer is "always on" and wasting power?

Do I put it before the transformer, so the duty cycle includes the surge of the transformer activation? Will the transient nature of the transformer smooth my square wave duty cycle? Will the constant cycling cause any damage?

I'm a bit in the dark here when it comes to these sorts of high-power things. Thanks for any help!

>>

File: thyristor_transformer.jpg (17KB, 500x306px) Image search:

[Google]

17KB, 500x306px

This is typically done with a Triac on the primary side.

I know nothing about peltiers but a recifier and large smoothing capacitor on the secondary side will smooth any kind of inductive kick you could get.

>>

>>948907

Oh, alright, thanks! Yep, rectification would be involved.

So the inrush current wouldn't be a significant problem? I'm not sure what the switching frequency would have to be right now, but since it's a thermal system it wouldn't have to be too fast.

Is there anything specific or any particular resources out there about operating transformers on duty cycles?

>>

>>948931

You're going to be switching at 50/60 hz if you're using triacs or thyristors.

That's the only frequency you would want to switch to anyway if you're using those iron transformers as opposed to ferrite ones used in smps supplies.

> So the inrush current wouldn't be a significant problem?

What kind of transformer are we talking about here ? Typically, no - it wouldn't.

> Is there anything specific or any particular resources out there about operating transformers on duty cycles?

I don't know any. Unless you're going to market your product and need to have it emi/iec approved, I wouldn't bother too much about that aspect. Test the circuit with a scope to see if you're getting wierd oscillations or similar garbage and you're done.

>>

>>948931

>>948903

>If I have a step-down transformer leading to a peltier heating element that I want to control via duty cycle, where do I put the relay?

>Do I put it between the transformer and load? >Does this mean that the transformer is "always on" and wasting power?

The amount of draw to keep the transformer energized will be minuscule, so it really doesn't matter.

>Do I put it before the transformer, so the duty cycle includes the surge of the transformer activation? Will the transient nature of the transformer smooth my square wave duty cycle?

Reactive filtering will smooth the square wave quite a bit, but inrush from such a small xfmr will be negligible.

>Will the constant cycling cause any damage?

No, just don't intentionally demag the core every time.

>So the inrush current wouldn't be a significant problem? I'm not sure what the switching frequency would have to be right now, but since it's a thermal system it wouldn't have to be too fast.

Shit, inrush is going to be +/- 5% load and will decrease the faster you switch (up to like 100hz, if it's faster than that you should do it on the secondary side)

>Is there anything specific or any particular resources out there about operating transformers on duty cycles?

The transformer is a hunk of iron and copper. It doesn't give a fuck unless you run it too hot. If you don't exceed the VA or current rating of the secondary you can usually run them 100% indefinitely. Your peltier will develop a short sooner than any consumer grade transformer - I always recommend properly sized, localized overcurrent protection for induction devices, though.

Thread posts: 5

Thread images: 2

Thread images: 2